As global supply chains grow more complex, manufacturers are facing increased attention on how they set prices for transactions between related entities. Transfer pricing for manufacturers isn’t just a legal formality, rather it plays a vital role in shaping financial performance, minimizing risks, and supporting global growth.

At Commenda, we recognize the unique challenges manufacturers encounter when it comes to transfer pricing. That’s why this article dives into the strategies that work, the compliance standards that matter, and the role technology plays in simplifying and strengthening your approach to transfer pricing in today’s complex manufacturing landscape.

What is Transfer Pricing in the Manufacturing Industry?

Transfer pricing in the manufacturing industry refers to the pricing of goods, services, and intellectual property exchanged between affiliated entities within a multinational enterprise. For example, when a subsidiary in Germany sells semi-finished components to its parent company in the U.S., the internal price assigned to that transaction is the transfer price.

These internal prices have significant implications for tax liabilities, operational efficiency, and financial reporting. Given the importance of accurately reflecting market conditions and complying with local laws, it’s critical to develop robust manufacturing industry transfer pricing strategies that align with both business goals and regulatory standards.

Why Transfer Pricing Matters for Manufacturers

Transfer pricing directly impacts profit allocation across different tax jurisdictions. Improper pricing can lead to base erosion, profit shifting, and substantial penalties from tax authorities. That’s why “transfer pricing compliance in manufacturing” has become a top priority for CFOs and tax directors.

For manufacturers, the stakes are even higher. Margins can be thin, and supply chains are complex. Misalignment in transfer pricing can disrupt operations, strain international relationships, and result in double taxation. Furthermore, it can trigger audits and long-term reputational damage. Transfer pricing compliance isn’t just about staying out of legal trouble, it’s about laying the groundwork for long-term success and sustainable growth.

Key Transfer Pricing Methods for Manufacturing Businesses

When it comes to setting internal prices between related entities, manufacturers need more than a one size fits all approach. The right transfer pricing method can help ensure fairness, transparency, and compliance while also supporting the unique operational realities of the manufacturing world. Here are the go to methods that work best in this space:

- Cost Plus Method: A staple for many manufacturers, especially contract manufacturers, the Cost Plus Method is all about building up from the basics. It starts with the actual cost of production and adds a reasonable markup to arrive at the transfer price. It is a clear, straightforward approach that works well when you have solid cost data and a relatively simple structure.

- Transactional Net Margin Method (TNMM): When finding exact comparables is tricky, and let’s be honest, it often is, TNMM steps in. Rather than focusing on gross margins, it looks at net profit relative to a key metric such as sales, costs, or assets. For manufacturers operating in more complex or integrated environments, this method offers the flexibility to reflect economic reality more accurately.

- Profit Split Method: In cases where manufacturing operations are deeply integrated across borders or business units, the Profit Split Method can be a smart choice. It allocates combined profits between entities based on each one’s contribution to the value chain. It is collaborative, fair, and particularly useful when both sides are bringing something significant to the table such as specialized intellectual property, research and development, or high value processes.

No two manufacturing businesses are exactly alike, so there is no single best method. The right fit depends on how your operations are structured, where your entities are located, and what kind of data you can reliably access. Making that choice carefully is key not just for compliance but for staying competitive in today’s global economy.

Manufacturing Transfer Pricing Risk Management

Managing transfer pricing in manufacturing isn’t just about compliance. It’s about avoiding costly surprises. Here are the big risks to watch out for:

- Tax Audits: Inconsistent paperwork or overly aggressive pricing can raise red flags. Clear, consistent documentation is key to staying audit ready.

- Double Taxation: When countries disagree on where profits should be taxed, businesses can get stuck in the middle, paying tax twice on the same income. Solid policies and defensible pricing help avoid this.

- Regulatory Changes: Tax rules evolve constantly. Staying informed and flexible is crucial to staying compliant.

Smart manufacturers manage these risks with detailed documentation, regular benchmarking, and real time monitoring. At Commenda, our software helps clients stay compliant and confident no matter how the rules shift. Schedule a Call today!

Global Transfer Pricing Issues in Manufacturing

For manufacturers with international operations, transfer pricing can quickly become a complex puzzle. Key challenges include:

- Differing Tax Laws: Every country has its own rules, and they don’t always align. What works in one place might cause issues in another.

- Currency Fluctuations: Shifting exchange rates can skew transfer prices, affecting both compliance and profitability.

- Customs vs. Tax Valuation: Customs authorities may demand one value, while tax authorities expect another. Meeting both can be tricky.

- BEPS Initiatives: OECD’s BEPS framework has raised the stakes with stricter documentation and transparency requirements.

Managing these challenges requires a centralized, adaptable approach. Commenda’s tools help manufacturers coordinate pricing strategies across borders, keeping things compliant, consistent, and under control.

Transfer Pricing Compliance in Manufacturing

Transfer pricing compliance isn’t just about ticking boxes, it’s about building a defensible story around how you price goods and services across borders. For manufacturers, that story needs to be crystal clear and fully documented.

- Master and Local Files: These are your core documents that explain your global pricing policies and how they apply in each country. They need to follow OECD standards and reflect your actual operations, not just theory.

- Benchmarking Studies: You can’t just make up prices. You need real market data to prove your prices are arm’s length. Solid benchmarking is the backbone of a defendable strategy.

- Intercompany Agreements: Every related-party transaction should be backed by a proper legal contract. These aren’t just formalities, they show intent, terms, and risk allocation.

When transfer pricing slips through the cracks, it’s more than just a financial slap on the wrist. It can put your brand under the microscope and keep you on regulators’ radar. That’s where Commenda comes in, automating the heavy lifting, tightening up your compliance, and keeping your global operations audit-ready without breaking a sweat.

How to Choose the Right Transfer Pricing Method for Your Manufacturing Business

There’s no one-size-fits-all method when it comes to transfer pricing. The right choice depends on how your manufacturing setup operates, how much risk each entity bears, and what data you have available.

- Nature of Your Operations: Are you a low-risk contract manufacturer just executing tasks? Or a full-risk entrepreneur making strategic decisions? Your method needs to match your role in the value chain.

- Data Availability: Methods like Comparable Uncontrolled Price (CUP) rely on reliable third-party data. In contrast, you’ll need to consider alternatives like the Transactional Net Margin Method.

- Profitability and Risk: Who takes on inventory risk, product development costs, or market exposure? The more risk you take, the more profit you should earn, and your method should reflect that.

For instance, for a low-risk contract manufacturer in a particular country, the Cost Plus Method could be the best choice, as it provides a simple and transparent way to mark up costs. On the other hand, a vertically integrated manufacturer-distributor operating in another country, where both production and distribution risks are shared, might benefit more from the Profit Split Method. This method helps fairly allocate profits based on how each entity contributes to the value chain.

The Role of Technology in Transfer Pricing for Manufacturers

As regulations grow tougher and data piles up fast, old school manual transfer pricing just can’t keep up. Technology isn’t a luxury anymore. It’s the backbone of staying compliant and competitive. Here’s a look at some of the key technology-driven factors shaping the transfer pricing landscape:

- Automation: Cut down on spreadsheet errors and repetitive tasks. Let the system handle the routine so your team can focus on strategy.

- Real-Time Reporting: Instant insights help you see if pricing policies are working—or if you’re drifting into risky territory.

- Document Generation: Automatically produce compliant master and local files, saving countless hours and reducing human error.

- Risk Alerts: Flag potentially non-compliant transactions before they become audit issues.

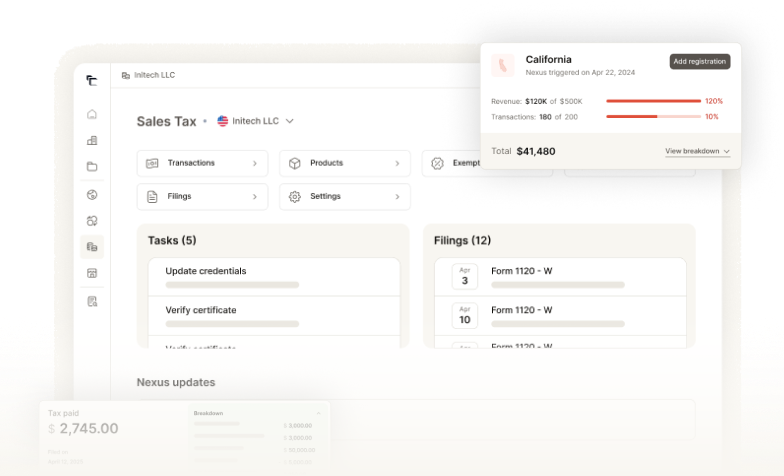

Commenda’s platform brings all of this together, integrating smoothly with ERP systems and giving you a clear view through user-friendly dashboards.

Why Choose Commenda for Transfer Pricing Solutions?

Transfer pricing in manufacturing is complex, but managing it doesn’t have to be. Commenda makes it simple with smart, scalable software built specifically for manufacturers.

- Full Automation: From gathering transaction data to generating reports, we take care of the heavy lifting.

- Seamless Integration: Our tools work with the systems you already use, so implementation is fast and painless.

- Global Compliance: We proactively monitor and adapt to OECD, IRS, and local regulatory requirements, ensuring your business remains fully compliant at all times.

- Built-In Risk Management: Custom alerts, audit trails, and scenario planning help you stay proactive and in control.

At Commenda, our team combines deep expertise in both manufacturing and international tax, delivering more than just software. We provide the confidence and peace of mind to navigate even the most complex challenges.

Conclusion

Transfer pricing for manufacturers has evolved, it’s no longer just a compliance requirement, but a crucial element of your overall business strategy. With increasing pressure from regulators and more complex global operations, it can feel overwhelming at times. But with the right tools and a thoughtful approach, you can transform that complexity into a competitive advantage.

At Commenda, we’re here to help you reduce risk, streamline your processes, and ensure compliance across every market you operate in. We know how critical it is to get it right, and we’ve built our solutions to give you the confidence to manage transfer pricing with ease and precision. Book a Demo today!